Here you will find helpful information about our Custom Tube Slides, including shipping and installation info, roto-molded plastic specifications and colors, and more.

Freight Shipping Cost

Although our website offers Free Shipping on orders over $99, this does not apply to our Custom Tube Slides due to the extremely variable cost of freight shipping. This cost typically ranges between $1,000-2,500 depending on the size of the slide and the distance it will need to travel. You can checkout through our website with the slide, after which we will contact you within 2-3 days with the final cost including shipping, of if you request a custom tube slide design, we will include the shipping cost with the quote. The delivery location must be able to accept semi-truck deliveries or may incur accessorial charges. Semi-truck deliveries require the ability to turn around or drive through the delivery location. Quoted delivery will be via semi-truck unless you advise otherwise. Off-loading and reloading to an alternate delivery vehicle will be at additional charge.

Installation Information

SwingSetMall.com is pleased to offer a quote for the professional installation of your custom tube slide. The cost can vary tremendously based on the challenges of the slide's design and the location of the project. The typical range falls between 30-60% of the slide's cost. Some of the larger and more complicated slide projects require the expertise of a professional playground installer to ensure proper and safe installation. If in doubt, we suggest you include professional installation with your Custom Tube Slide quote request, or contact us to discuss.

When ordering commercial-grade events like this, assembly instructions are not included. Commercial-grade events are intended to be installed by a professional playground contractor. If you do not order professional installation, you are responsible for the proper installation of the event. For orders that do not include professional installation, unless you advise otherwise, your slide will be shipped with "assemblies completed". "Assemblies completed" means that the event is assembled at the factory - holes drilled, hardware installed, etc. The event is then usually partly dis-assembled for transport.

IMPORTANT ACCESS INFORMATION!

- Minimum installation site access dimensions for materials: 38" width, standard man-door height, and access for tube sections up to 10' long.

- Installations requiring a man-lift (typically slides with deck heights 12' and more) need a site access width minimum of 44" and standard door height.

Note that commercial grade components are warranted for one year against material and manufacturing defects.

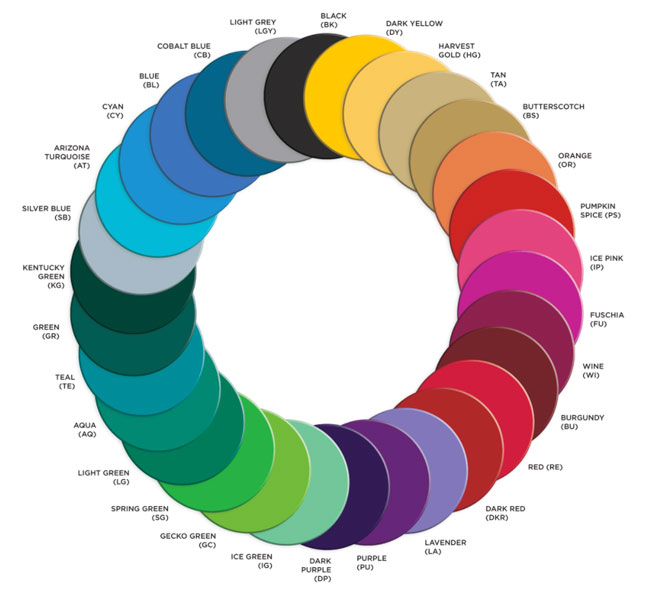

Tube Slide Roto-Molded Plastic Colors

This color table approximates the actual colors available in roto-molded plastic for Tube Slides*. However, because both computer monitors and resin batches vary, colors will also vary. If needed, we may be able to provide a few color samples in roto-molded plastic on request.

* Please note that Pumpkin Spice and Spring Green colors are not available for our tube slides as these colors tend to have issues with bubbling for single-wall plastic roto-molding. Also, White is not shown in this color chart, but is an available color option.

Roto-Molded Plastic Specifications

The roto-molded material used in creating these slides meets all required standards for use on playgrounds (indoor and out) in the USA. Roto-molded plastic specifications:

- 1st quality linear low density Polyethylene (LDPE)

- Rotational molded with mold-in graphics (where applicable)

- 3/8” wall thickness

- 2,550 psi tensile strength (ASTM D638)

- Melt index per ASTM D1238

- Density per ASTM D4883

- Peak crystallization temperature per ASTM D3418

- Flexural modulus per ASTM D790 Procedure B

- Deflection temperature under load per ASTM D648

- Environmental stress crack resistance, F50 per ASTM D1693 Condition A

- UV stabilized / UV 8 Rating (tested per ASTM G155 cycle 1 guidelines)

- Anti-static inhibitors

- Testing for all grades listed under UL-94HB providing the part is greater than 58 mil in thickness. Testing reference number with UL is E117534(N)

- ASTM E-662 (NFPA 258) on LL-8361 and LL-8461 for specific optimal smoke density is less than 450 in the flaming mode.

- Ran LL-8361 via U.S. Testing Labs in New Jersey for flame spread index and achieved a rating of 80. This procedure was ASTM E-84-89(a), often referred to as the Steiner Tunnel Test.

If more detail is required, download Comprehensive Specification & Test Information.

Tube Slide Metal Support Structure Colors

This color table approximates the standard colors available for the major elements of the metal support structure for Tube Slides. All fittings and hardware are normally provided in Silver. Because computer monitors vary, the pictured colors are approximate. Samples in metal are not available.

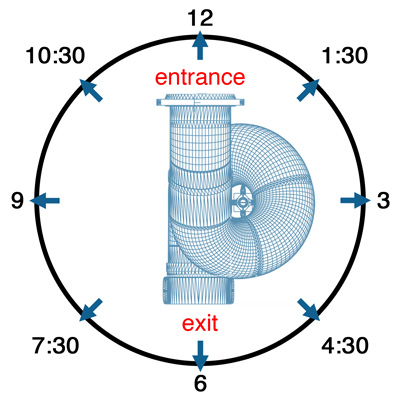

Spiral Slide Exit Directions

When designing your custom tube slide, the direction in which your slide exits can typically be adjusted with the use of certain elbow and straight tube pieces. To determine your desired exit direction, use the following chart, where the slide entrance is 12:00 o'clock.

For example, in this drawing, the slide is exiting at 6 o'clock. If it exited to the "Right" this would be at 9 o'clock, and "Left" would be at 3 o'clock, since it is from the point of view of the entrance.

Weight Limit

All commercial-grade tube slides are intended for use by one user at a time with a maximum weight of 250 lbs. For possible determination of a load rating beyond this recommendation, a load-bearing calculation by a certified engineer can be ordered at additional expense.